Driving Value Through

Sustainability.

97%

Carbon footprint reduction in energy efficiency initiatives

100%

Renewable energy integration in project execution

Zero

Liquid Discharge (ZLD) Implementation across facilities

30%

Lower energy consumption via smart HVAC and power optimization

80%+

Water recycling & reuse in industrial processes

Why choose us?

At EnGenius Matrix, we bring unparalleled expertise, innovative solutions, and a commitment to excellence that sets us apart. Our holistic approach ensures efficiency, sustainability, and technological advancement across industries.

Lifecycle Expertise

We collaborate closely with clients, leveraging data, market insights, and innovation to create seamless, end-to-end solutions that integrate every aspect of the project lifecycle.

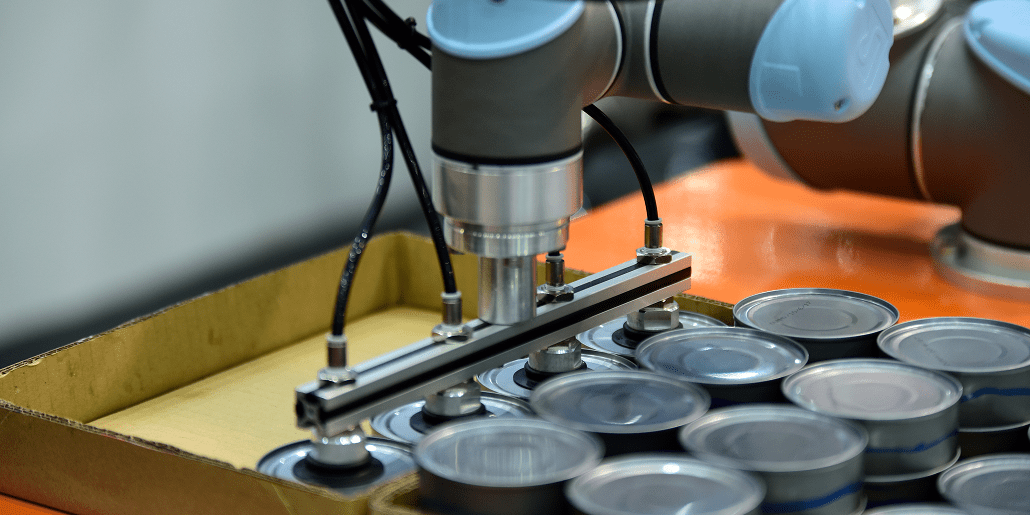

Frugality and Innovation

We blend cost-effectiveness with innovation, using AI-driven automation, digital twins, and lean engineering to maximize ROI, reduce costs, and enhance efficiency sustainably.

Safety and Inclusivity

Our top priority is safety by design. We implement proactive measures and ensure inclusivity in every project, fostering a secure and collaborative environment

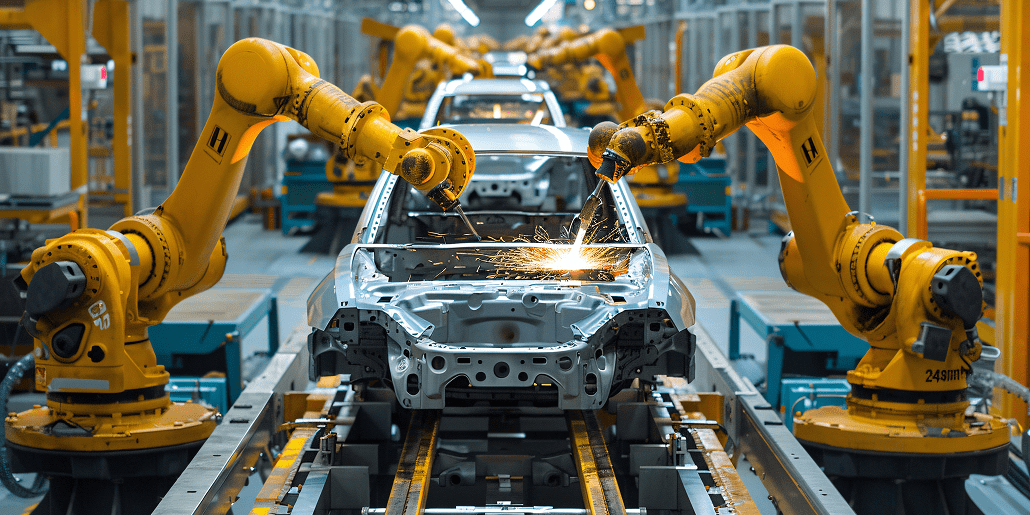

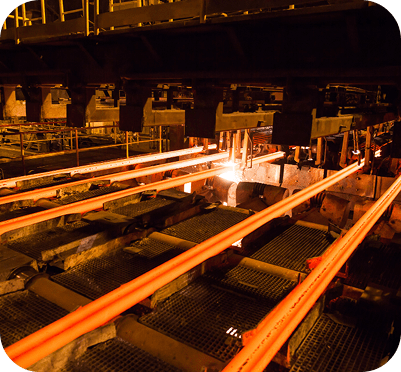

Relevant Industry Experience

With a legacy of impactful projects, we drive cost savings, efficiency, and sustainability through engineering excellence, supply chain automation, and green energy solutions.

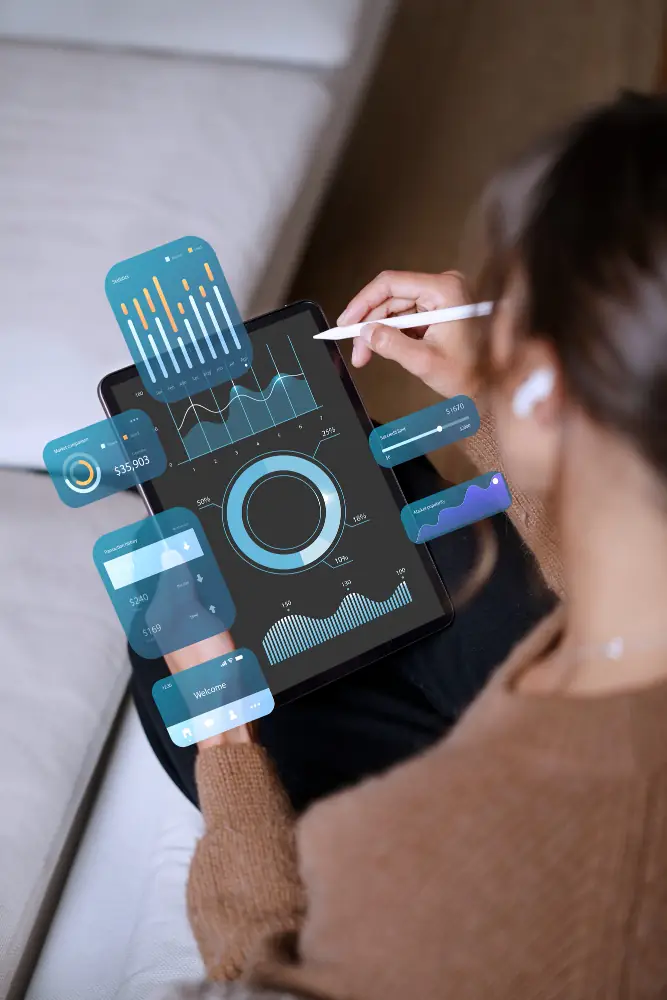

Data-Driven & AI-Powered Solutions

We integrate AI, IoT, and machine learning to enable real-time decision-making, predictive maintenance, and intelligent automation, keeping industries ahead in the digital era.

Sustainability at the Core

We drive a greener future through carbon reduction, energy-efficient infrastructure, and renewable energy, ensuring sustainable, long-term benefits for businesses.

Scalability & Future-Readiness

Our modular, scalable solutions evolve with your business, integrating AI automation, robotics, and smart supply chains for greater agility and resilience.